Introduction

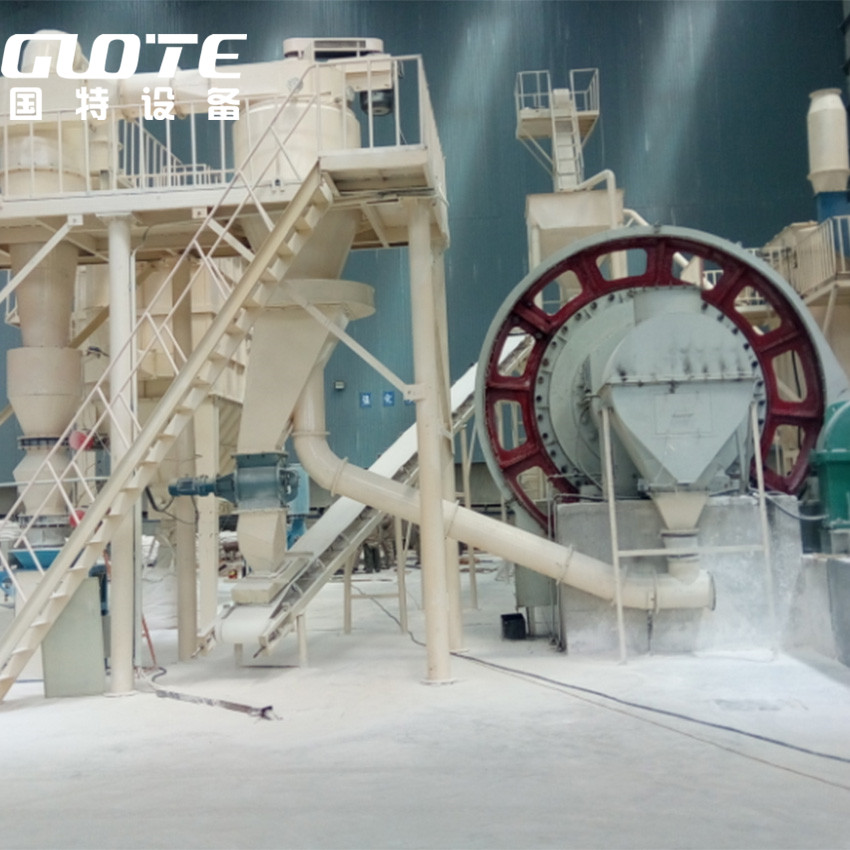

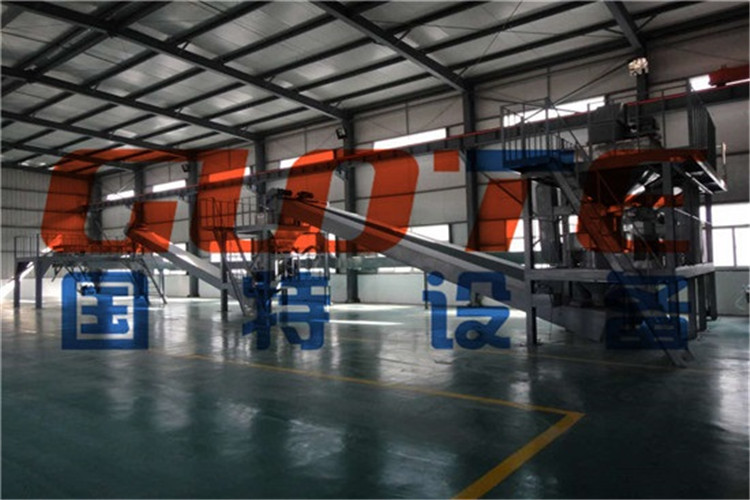

It mainly used for mineral processing , chemical,medicine,building materials,quartz powder for plate etc.This product can used to pruduce high purity quartz powder with 200-300mush,The product has many advantages such as high purity ,Good whiteness and stable granularity and so on.The whole production line can realize automatic control and stable operation.

Outstanding advantages

The materials which less than 10mush ,from feeding apparatus through the feeding hollow shaft screw enter into mill warehouse homogeneous ,the warehouse is equipped with a ceramic liner plate with steel and jade balls of different specifications , The centrifugal force generated by the rotation of the cylinder brings the dielectric ball to a certain height and then falls down , Impact and grinding on materials.the powder that meets the requirement is discharged through the discharge grate,finish the milling operation.After grinding, the material enters the classifier from the inlet,by adjusting the speed of the classifying wheel (frequency control, stepless speed regulation)and reasonable secondary wind , a reasonable and stable gas-solid two-phase flow is formed in the grading zone,The interaction between centrifugal force and the negative pressure of the fan is generated by the rotation of the classifying wheel to realize effective grading of materials.The coarse particles are returned to the ball mill by the coarse material return device to continue grinding, and the finished products are packaged by the automatic packaging machine.The whole system is equipped with a dust precipitator using more advanced electromagnetic pulse automatic ash removal,the dust is filtered by the filter bag after the dust - carrying gas enters the dust collector,dust attached to the outer surface of the filter bag is scattered at the bottom under the action of pulse blowback gas. The filtered clean gas is discharged into the atmosphere through the fan.

Introduction of working principle

Introduction of Technical Parameters

|

Model

|

Ball mill machine

|

|

Total Power

|

Capacity

|

Fineness

|

Classification accuracy

|

Filtration area

|

Dust concentration

|

Working system

|

|

GMF-100

|

Φ1500*5700

|

GF100

|

≤145

|

1.2-8

|

5-50

|

D97

|

≥70

|

≤40

|

Continuous

|

|

GMF-200

|

Φ1830*7000

|

GF200

|

≤225

|

3.5-4

|

5-50

|

D97

|

≥100

|

≤40

|

|

GMF-400

|

Φ2200*7500

|

GF400

|

≤345

|

5-6

|

5-50

|

D97

|

≥120

|

≤40

|

|

GMF-500

|

Φ2200*7500

|

GF500

|

≤500

|

5-7

|

5-50

|

D97

|

≥200

|

≤40

|

|

GMF-600

|

Φ2400*7500

|

GF600

|

≤550

|

7-9

|

5-50

|

D97

|

≥300

|

≤40

|

|

GMF-800

|

Φ2600*8000

|

GF800

|

≤665

|

8-12

|

5-50

|

D97

|

≥350

|

≤40

|

|

GMF-1000

|

Φ2800*8000

|

GF1000

|

≤780

|

10-15

|

5-50

|

D97

|

≥400

|

≤40

|

|

GMF-1200

|

Φ3200*9000

|

GF1200

|

≤1200

|

15-20

|

5-50

|

D97

|

≥500

|

≤40

|