Ball mill is a key equipment for crushing materials after being broken. It is widely loved by people in mineral processing, building materials and chemical industry for its characteristics of high efficiency, energy saving, intelligence, environmental protection, low carbon, durability and long life.

There are many factors affecting the output and quality of ball mill, which can be generally divided into three categories: process factor, mechanical factor and management factor.From the perspective of production process, the main influencing factors are as follows:

1. Particle size of feed material

The particle size of the input material affects the output and quality of the ball mill. If the particle size is small, the output and quality of the mill are high and the power consumption is low.Large particle size, the mill output, low quality, high power consumption.

2. The grindability of materials.

The grindability of materials refers to the degree of grindability of materials. According to the national standard, the grindability index Wi (KWH /t) is used to indicate the grindability.The smaller the value is, the better the material is grinded, and vice versa.

3. Water content of grinding materials

Ball mill grinding can be divided into dry and wet two ways, for the dry grinding method, the water into the grinding material has a great impact on the output and quality of the mill, the higher the water into the grinding material, easy to cause full grinding or paste grinding, reduce the grinding efficiency, the lower the mill output.Therefore, the moisture content of larger materials, into the mill before drying is very necessary.

4. Temperature at which the material is to be grinded

Too high temperature of grinding material and impact friction of grinding body will cause excessive temperature in grinding, sticky ball phenomenon, reduce grinding efficiency and affect the output of grinding machine.At the same time, the cylinder of the mill is affected by thermal expansion and the mill runs safely for a long time.Therefore, the temperature of the materials must be strictly controlled.

5. Fineness requirement of grinding material

The finer the fineness requirement is, the lower the yield will be; otherwise, the higher the yield will be.For some fields, too much emphasis on fineness is not in line with the requirements of economic production.For example, in the cement industry, the actual production shows that when the product fineness is within the range of 5~10%, the yield will be reduced by 5% for every 2% reduction in fineness.Therefore, choosing the right product fineness is also an important factor to improve the output and quality of ball mill.

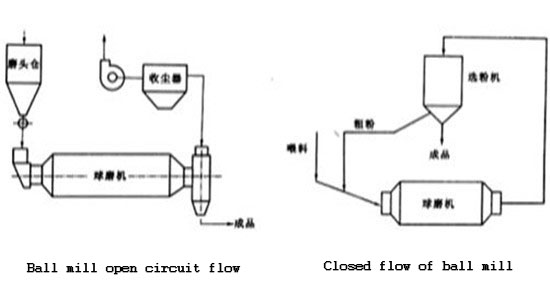

6. Grinding process flow

For ball mill of the same specification, the output of closed flow is 15 ~ 20% higher than that of open flow.It is an important factor to select proper powder selection efficiency and cycle load rate in closed circuit operation.

7. Choose powder efficiency

The selection efficiency of closed circuit mill has great influence on the output of mill.Generally speaking, the efficiency of the separator is high, which can improve the grinding efficiency of the mill.However, the separator itself can not play the role of grinding, so the role of the separator must be with the grinding role of the mill, in order to improve the output of the mill.Production practice has proved that the efficiency of a closed circuit long mill separator is generally controlled in 50~80%.The optimum efficiency of powder selection should be determined by many experiments.

8. Cycle load rate

Cycle load rate is the ratio of the amount of powder (i.e. coarse powder) and the amount of finished product.In order to improve the grinding efficiency of the mill and reduce the phenomenon of excessive grinding in the mill, the cycle load rate should be appropriately increased.However, if the cycle load rate is raised very high, it will make too many materials in the mill, but reduce the grinding efficiency.

9. Add grinding aid

Some grinding AIDS will affect the grinding effect, because most of the commonly used grinding AIDS are organic materials with strong surface activity. In the grinding process of materials, they can adsorb on the surface of materials, accelerate the crack growth in the crushing of materials, reduce the mutual bond between fine powder, improve the grinding efficiency, which is conducive to the energy saving and high yield of ball mill.

10.ratio of grinding media to material

The ball material ratio is the ratio of the mass of the grinding body to the mass of the material.If the ball material ratio is too large, it will increase the useless loss of the impact friction between the grinding body and the liner, increase the power consumption and reduce the output.

In addition to process factors, the type, parameters and production, maintenance, maintenance personnel also affect the output and quality of the ball mill.The energy saving and high yield of ball mill is a systematic project, each link is connected with each other, and restrict each other.